Why UV light exposure in the workplace is still being overlooked

Written by Dan Arnold from Arden Ultraviolet Limited

Ultraviolet (UV) light has long been an integral part of many industrial and commercial processes.

From UV-A inspection equipment and UV-C germicidal lamps, to bonding, curing, and coating systems.

Yet despite its widespread use, artificial UV light exposure remains a frequently overlooked occupational hazard.

The reasons behind this are multifaceted, ranging from legacy equipment to misconceptions about UV light risks. The implications can have real consequences for worker health and regulatory compliance.

A legacy of under-assessment

One of the most significant contributors to this oversight is historical.

Many workplaces adopted UV-based technologies decades ago, well before the introduction of the European Physical Agents (Artificial Optical Radiation) Directive (2006/25/EC) and its transposition into UK law in April 2010.

Equipment and processes that were implemented before these regulatory frameworks may never have been formally assessed for UV exposure risks.

In many cases, these processes simply continued under the assumption of safety, without updates to reflect evolving understanding and legal requirements.

The natural vs artificial UV misconception

Another common misunderstanding is the tendency to downplay artificial UV exposure risks by comparing them to natural sunlight.

While it’s true that we all encounter UV radiation outdoors, occupational exposure from artificial sources is governed by specific statutory limits (and for good reason).

Artificial sources often emit UV radiation at higher intensities and narrower wavelengths, which can significantly increase the risk of skin damage, eye injuries, and even long-term health conditions.

Importantly, the workplace exposure limits only apply to artificial sources, making this distinction vital for employers and safety professionals.

Lack of internal expertise and awareness

Artificial UV light safety is a technically complex area.

Many organisations simply lack in-house expertise to fully understand the risks, interpret exposure limits, or carry out appropriate assessments. The absence of hazard awareness training for employees can further compound this risk.

In workplaces using UV-A systems, for instance, the lack of immediate adverse symptoms (unlike UV-B and UV-C related photo keratitis and erythema) can result in a false sense of security, even when statutory exposure limits are exceeded.

Inadequate personal protective equipment (PPE)

There is a widespread belief that basic PPE such as UV-blocking spectacles or gloves is sufficient protection.

However, this overlooks the fact that exposed skin on the face, neck, and arms may still be at risk, especially during prolonged or repeated exposure. Comprehensive protection involves more than PPE, it requires proper engineering controls, training, and exposure assessments.

Manufacturer information gaps

While manufacturers are required to classify equipment risk groups and provide technical data, they are not obligated to assess risk within a specific operational context.

This creates challenges for employers conducting their own risk assessments.

Without clear guidance on intensity, exposure duration, and correct usage, many users struggle to meet legal requirements, often unintentionally falling short.

Complexity of exposure limits and measurement

Calculating personal exposure to UV light is not straightforward. Limits such as the 30 J/m² effective irradiance threshold for skin exposure, or the 10,000 J/m² limit for ocular exposure to UV-A, require specialised equipment, software, and expertise.

Many companies attempt in-house assessments without the proper tools or knowledge, resulting in inaccurate data and non-compliance.

Unintentional use and misapplication

In some cases, organisations are completely unaware that they are using hazardous UV sources. For example, we’ve encountered:

- UV-C tubes installed in insect traps or kitchen fly killers, purchased without awareness of associated risks.

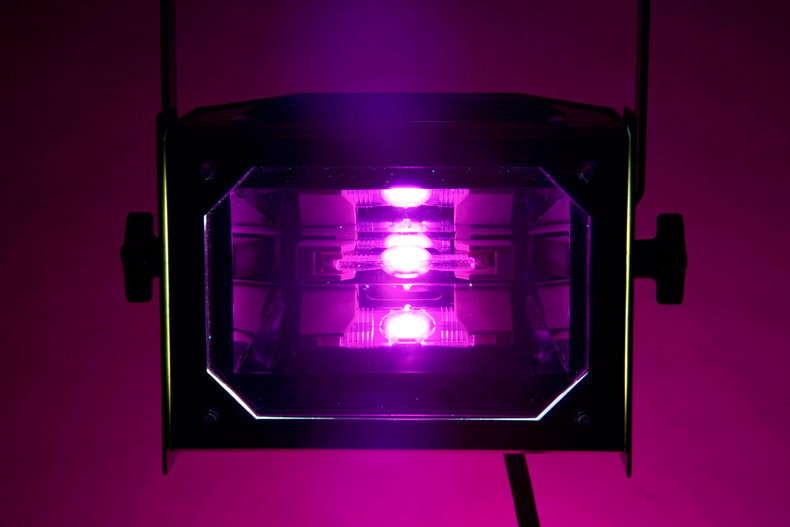

- Special effects lighting emitting UV radiation, often with damaged filters.

- Fluorescent “white light” systems where the protective UV filters degrade over time, leading to accidental exposure.

These examples underscore the importance of education, clear labeling, and thorough commissioning checks before UV equipment is deployed.

Supporting employers in managing UV risk

As specialists in artificial UV risk assessment, we offer a comprehensive suite of services to help organisations meet their statutory obligations and protect their workforce. These include:

UV risk management training

Tailored for employers already using or planning to introduce UV processes into their operations. This course provides essential understanding of legislation, safe system design, and control strategies.

UV exposure measurements and assessments

We use industry-standard tools to measure, interpret, and document worker exposure levels, helping you demonstrate compliance with exposure limits.

Employee UV hazard awareness training

Often overlooked, this training is a legal requirement for any employee who may be exposed to artificial UV, even when exposure is contained under normal conditions. Faulty controls or lack of procedural understanding can still lead to accidental overexposure, making awareness training a vital safety measure.

The bottom line

Artificial UV light exposure remains an underestimated risk in many workplaces. Whether it’s legacy equipment, lack of internal expertise, misunderstood PPE practices, or simply a lack of awareness that UV is even present, the consequences of inaction can be serious – from employee injury to regulatory breaches.